Cable Tray Manufacturers in Pune

S K Enterprises is leading Cable Tray Manufacturers in Pune and Suppliers in Pune. We are focused on offering high quality, reliable, and durable cable management solutions to our industrial, commercial, and residential customers. We have a large variety of cable trays such as ladder, perforated; solid-bottom, wire mesh, FRP cable trays, raceway cable tray and electrical cable tray that may be used to suit the needs of various projects. Our priorities are structured cable administration, high security and durability in performance and all installations are efficient, extendable and made to withstand harsh conditions

What is cable tray?

It is a structural implementation, in which electrical cables, data cables, or communication wires are supported, arranged, and directed through a building or an industrial setup. It also offers a secure and convenient route to cables, minimizing the chances of its destruction and simplifying the process of maintenance.

Types of Cable Tray:

We are notable Cable Tray Manufacturers in Pune and here are the various types of cable tray we offer:

By Design

- Ladder type cable trays: This is a tray is sealed at the sides and the rungs are interconnected, which gives the tray great strength and provides ventilation. They are suitable in high temperature and heavy duty cables.

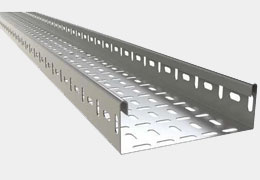

- Perforated Cable Trays: These are trays with a solid base and holes which enable moderate ventilation of the trays and at the same time keep the medium-duty cables out of dust and dirt. They are often applied in the indoor applications.

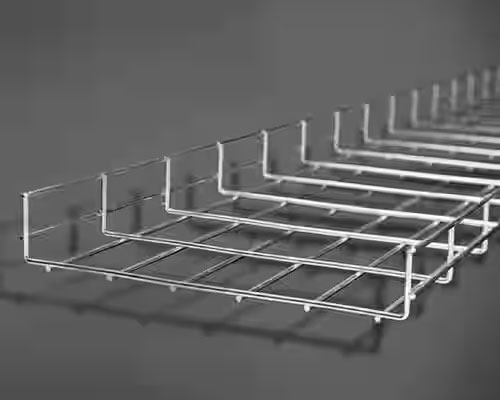

- Wire Mesh Cable Trays: The trays are made of welded wires thus they are light, flexible, and well-ventilated. They are normally applied in data and telecommunications cables.

- Channel Cable Trays: Channel trays are a range of single-meta channel that is narrow. They suit well when the cables are light in weight in case of indoor and visible installations.

- Raceway Cable Trays: These trays maintain a small enclosed structure suitable for application in office environments.

- Electrical Cable Trays: The generic designation includes a variety of supporting structures that experts use to manage electrical cables.

By Material

- Galvanized Steel: GI cable trays are resistant to corrosion and are very strong. Galvanized cable trays are usually applied in the industrial setting and outside.

- Aluminium: These trays are light, strong and very corrosive resistant. They suit the outdoors or the corrosive environment perfectly well.

- Fiberglass (FRP): FRP cable trays are lightweight, corrosive and chemical resistant as well as non-conductive. They can also withstand impacts as well as fire, thus they are safe in installing sensitive installations.

Perforated Cable Tray

Galvanized Cable Tray

Ladder Type Cable Tray

Raceway Cable Tray

MS Cable Tray

FRP Cable Tray

PVC Cable Tray

Electrical Cable Tray

Hot Dip Galvanized Cable Tray

Technical Specifications of Cable Tray:

| Specification | Details |

|---|---|

| Material | FRP, Metal (Steel, Aluminium or Stainless Steel) |

| Width | 50 – 1000 mm. |

| Height (Side Wall Depth) | 25– 150 mm. |

| Thickness | Metal: 1.6 mm – 3 mm; FRP: 3 mm – 6 mm |

| Length per Section | 2.5 m – 3 m |

| Load Capacity | Ladder trays: heavy load; Perforated/Mesh trays: light to moderate load. |

| Surface Finish/Coating | Hot Dip Galvanized, Powder Coated, or Epoxy Coated. |

We are not only Cable Tray Manufacturers but also top Manufacturers of Wire Mesh Cable Trays in Pune.

Benefits of Cable Tray:

We as top Cable Tray Suppliers in Pune our trays are beneficial in following ways

- Efficient Cable Management: MS cable trays will make sure that there are no tangles and clutters and that all the electrical and communication cables are properly organized. This makes the process of inspection, maintenance and future expansions easy.

- Durable and Long-Lasting: Cable trays can be made of metal, FRP, or PVC cable tray and are recommended to withstand heavy loads and severe working conditions that guarantee significant performance during prolonged periods.

- Enhanced Safety: The cable trays can remove instances of electrical risks and fire because of cable destruction, overheating and unintended contact therefore the working environment is safer.

- Cost and Time Efficiency: The cable trays take a shorter time than the conventional conduit systems and save labor and time. They can also expand in the future easily because of their modular design.

- Versatile and Scalable: Hot dip galvanized cable trays are available in a variety of forms such as ladder, perforated and mesh trays which can be applied in many industries; hence they can be used in diverse applications.

Applications of Cable Tray:

As Cable Tray Suppliers in Pune our trays are prominently used in following areas:

- Industrial Plants: Cable trays are used in factories, refineries and power plants and offer a high level of support to heavy electrical cables in large operations.

- Commercial Buildings: Cable trays are used in offices, malls, hospitals and shopping complexes to wire them in an organized manner to facilitate their maintenance and also to increase their safety.

- Data Centres: Cable trays are effective in grouping heavy power and data cable thus eliminating the clutter and enabling quick upgrades or changes when required.

- Infrastructure Projects: Cable trays are used in airports, metro stations and highways as a means of electrical distribution, thus ensuring the efficient running of lighting, communication and power systems.

- Residential Projects: Cable trays in apartments and housing complexes keep the wiring tidy and minimise the risks, and make future electrical modification easier.

Why choose us?

- High Quality Materials- FRP, steel, aluminium and PVC are used to provide long lasting, corrosion and safe cable tray solutions.

- Tailor Made Solutions- Our trays can be found in different sizes, type and finish to suit special project needs.

- Professional Support and Timely delivery- We offer professional support and guarantee timely delivery to facilitate smooth execution of the projects.

S K Enterprises is reliable Cable Tray Manufacturers in Pune and Suppliers in Pune. We offer high-quality cable management systems that are easy to install and enhance safety and long term reliability. Our products are designed to support a very wide range of applications including industrial plants, commercial buildings, data centres and residential projects. Durability, efficiency, and scalability ensure that every client receives the solutions that would help maintain the high safety of operations, reduce the maintenance effort, and meet the highest standards in the industry. Get in touch with us to know more.

Related Searches :Cable Tray Manufacturers near me in Pune, Cable Tray Suppliers in Pune, Cable Tray Manufacturers in Hadapsar, Cable Tray Suppliers in Bhosari, Cable Tray Manufacturers in Kothrud, Cable Tray Suppliers in Wakad, Cable Tray Manufacturers in Wakad, Cable Tray Manufacturers in Baner, Cable Tray Manufacturers in Shivaji Nagar, Cable Tray Manufacturers in Pimpri, Cable Tray Manufacturers in Aundh, Cable Tray Manufacturers in Wagholi, Cable Tray Manufacturers in Pimple Saudagar, Cable Tray Manufacturers in Katraj, Cable Tray Manufacturers in Kharadi, Cable Tray Manufacturers in Chinchwad, Cable Tray Manufacturers in Swargate, Cable Tray Manufacturers in Camp, Cable Tray Manufacturers in Bhosari, Cable Tray Manufacturers in Chakan, Cable Tray Suppliers in Chakan.